Ultra Violet curing is a fast developing drying method in printing industry. It has a wide

application in Varnish Coating and Printing with UV inks on various substrates like Papers, Boards, Wood,

Glass, Plastic etc., It gives High gloss finish matt finish and it gives highly chemical and water resistive surface. UV consumes

less power and Eco friendly because of no volatile emissions. It dries the ink or varnish instantly which leads to less dot

gain and good adherence on the plastics substrates like PP, BOPP, PVC etc.,

We deliver total uv solution for your industry. The below mentioned are the product for your business needs.

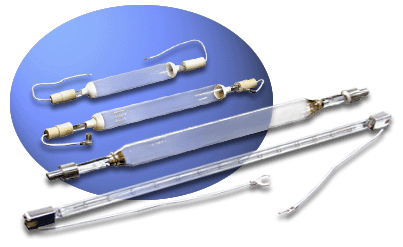

Mercury Vapour Lamps or Metal Halide UV Lamps are used in the conventional UV system. The mercury vapour lamp is the medium pressure

vapour lamps commonly used in curing applications. Metal Halide lamps are also used now to avoid mercury. These are all made up of

Quartz tubes with ceramic holders.

The Lamp wattage will vary as

Below mentioned are few models for Conveyor UV (Conventional UV system)

| Curing width | 12 inches |

| Curing Speed | 25/40 mtrs per min - Variable with AC drive |

| Conveyor Belt | Teflon Mesh |

| Cooling | Air Cooled by a blower |

| Lamp Power | 2.4 KW / 3.6KW |

| Safety | Protective Cover to prevent Direct Exposure of UV radiation Limit Switch control to Switch off the Lamp when Dome Open Emergency Switches at delivery |

| Application | Screen printing & Coating |

| Substrates | Paper, Boards, Wood, Glass, Plastics, Tiles, Tin Metal |

| Curing width | 20 inches |

| Curing Speed | 25/40 mtrs per min - Variable with AC drive |

| Conveyor Belt | Teflon Mesh |

| Cooling | Air Cooled by a blower |

| Lamp Power | 4 KW / 6 KW |

| Safety | Protective Cover to prevent Direct Exposure of UV radiation Limit Switch control to Switch off the Lamp when Dome Open Emergency Switches at delivery. |

| Application | Screen printing & Coating |

| Substrates | Paper, Boards, Wood, Glass, Plastics, Tiles |

| Curing width | 30 inches |

| Curing Speed | 25/40 mtrs per min - Variable with AC drive |

| Conveyor Belt | Teflon Mesh |

| Cooling | Air Cooled by a blower |

| Lamp Power | 6 KW / 9KW |

| Safety | Protective Cover to prevent Direct Exposure of UV radiation Limit Switch control to Switch off the Lamp when Dome Open Emergency Switches at delivery |

| Application | Screen printing & Coating |

| Substrates | Paper, Boards, Wood, Glass, Plastics, Tiles, Tin Metal |

| Curing width | 30 inches |

| Curing Speed | 100 mtrs per min - Variable with AC drive |

| Conveyor Belt | Teflon Mesh |

| Cooling | Air Cooled by a blower |

| Lamp Power | 2 x 4 KW / 2 x 6KW. |

| Safety | Protective Cover to prevent Direct Exposure of UV radiation Limit Switch control to Switch off the Lamp when Dome Open Emergency Switches at delivery |

| Application | Automatic Screen printing & Offset Attachment at Delivery |

| Substrates | Paper, Boards, Plastics |

| Curing width | 40 inches |

| Curing Speed | 25/40 mtrs per min - Variable with AC drive |

| Conveyor Belt | Teflon Mesh |

| Cooling | Air Cooled by a blower |

| Lamp Power | 8 KW / 12 KW / 16 KW |

| Safety | Protective Cover to prevent Direct Exposure of UV radiation Limit Switch control to Switch off the Lamp when Dome Open Emergency Switches at delivery |

| Application | Screen printing & Coating |

| Substrates | Paper, Boards, Wood, Glass, Plastics, Tiles |

| Curing width | 40 inches |

| Curing Speed | 100 mtrs per min - Variable with AC drive |

| Conveyor Belt | Teflon Mesh |

| Cooling | Air Cooled by a blower |

| Lamp Power | 2 x 8 KW / 2 x 12 KW / 2 x 16 KW |

| Safety | Protective Cover to prevent Direct Exposure of UV radiation Limit Switch control to Switch off the Lamp when Dome Open Emergency Switches at delivery |

| Application | Automatic Screen printing & Offset Attachment at Delivery. |

| Substrates | Paper, Boards, Plastics |

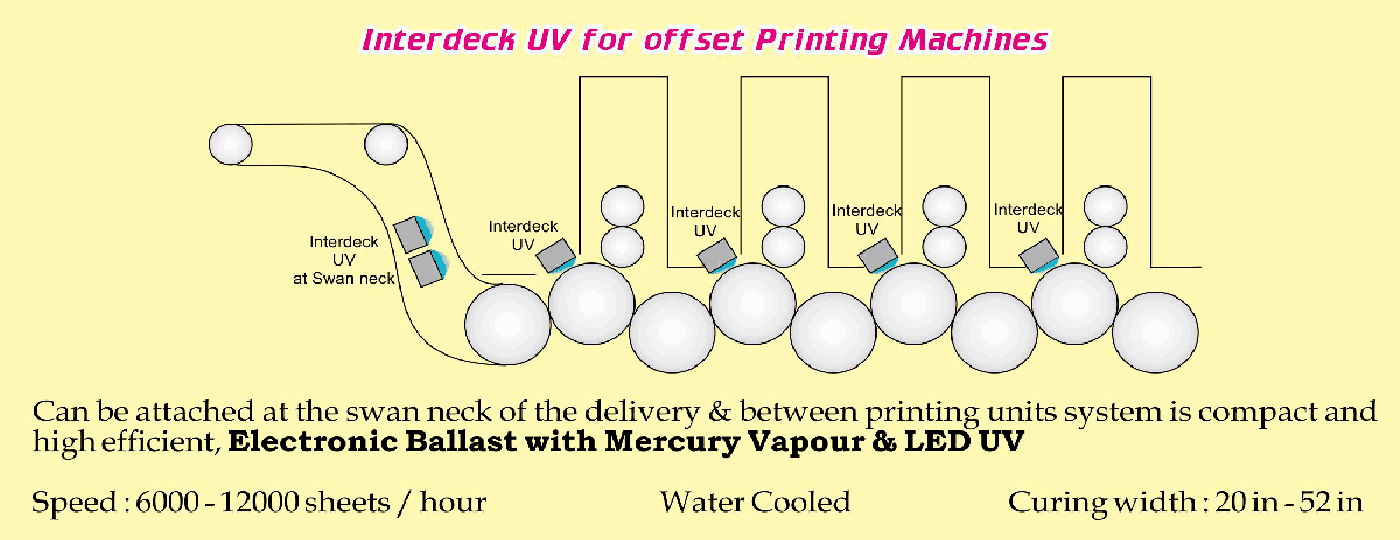

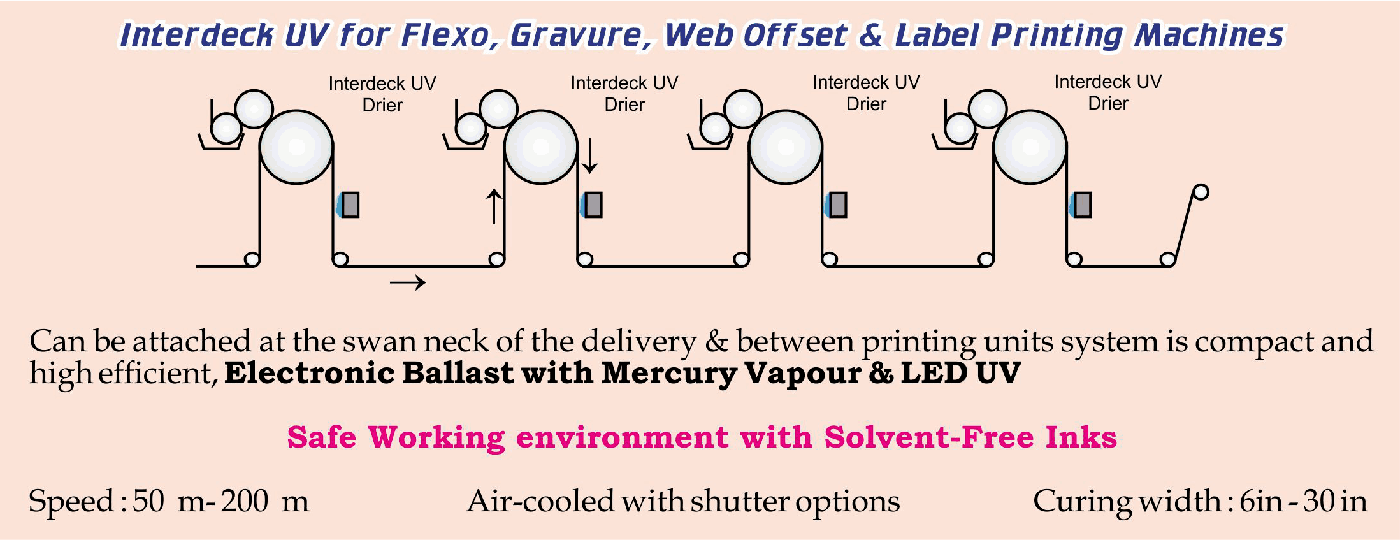

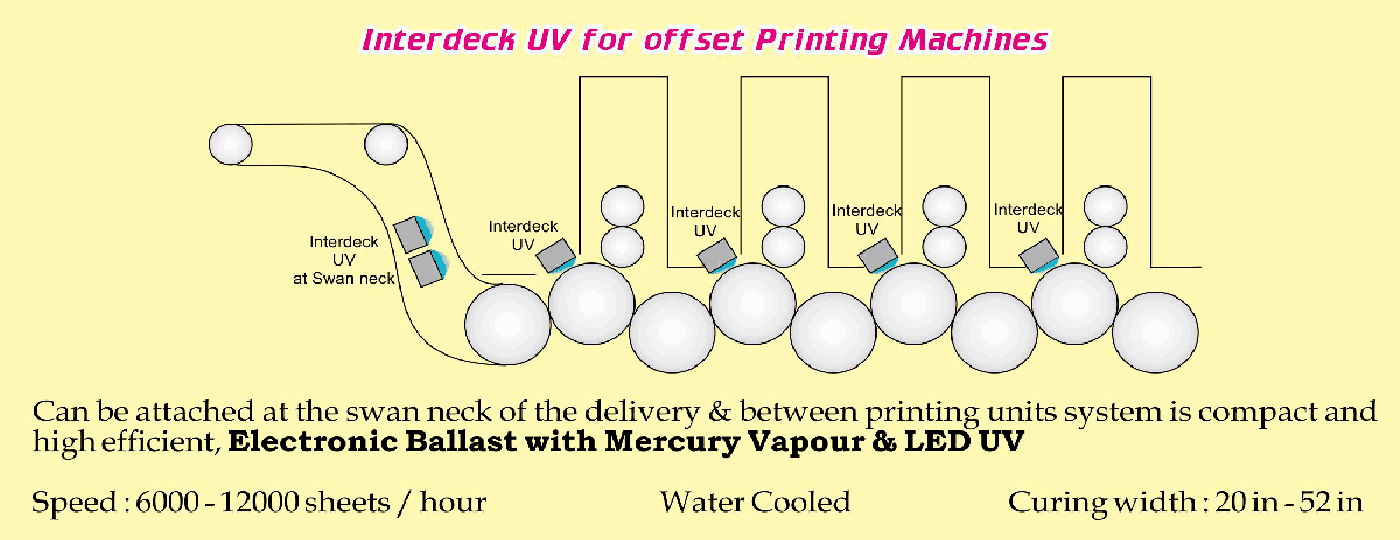

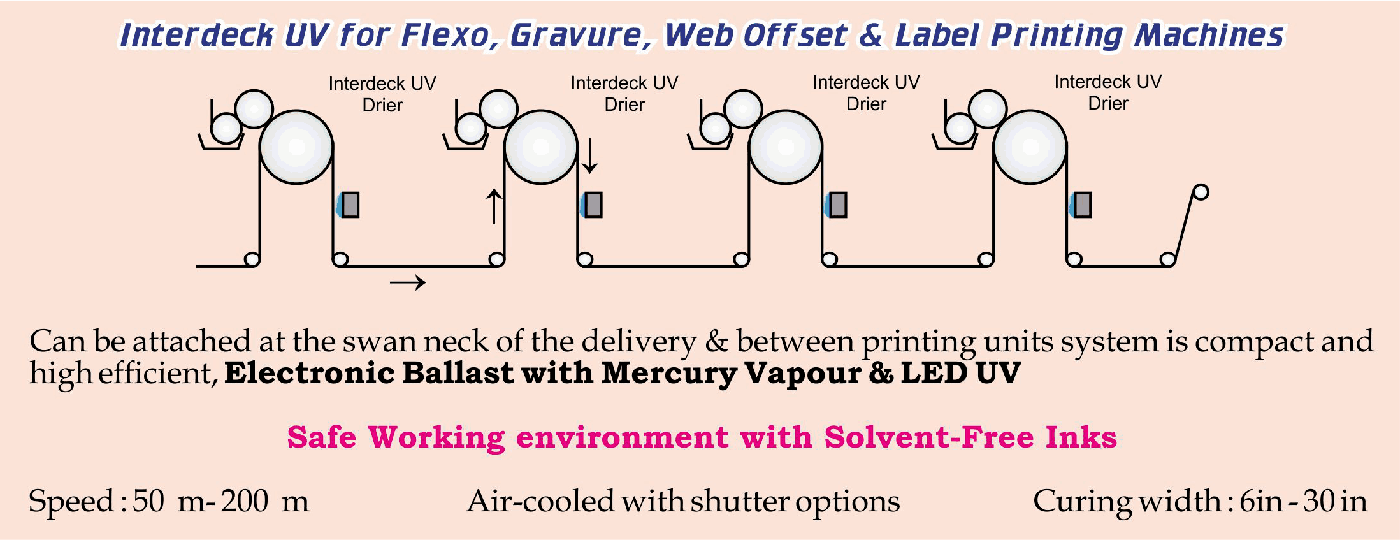

Below mentioned are few models for Interdeck UV (Conventional UV system)

| Curing width | 12 inches |

| Curing Speed | 150/200 mtrs per min |

| Cooling | Water Cooled 3/4 Ton capacity for a Lamp |

| Lamp Power | 3.6 KW / 4.8 KW |

| Power Supply | Transformer type with half- and full-power control Electronic Ballast type variable from 10% to 100% |

| Safety | Shutters Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Flexo and Label printing machines. |

| Substrates | Paper, Boards , Plastics |

| Curing width | 20 inches |

| Curing Speed | 150/200 mtrs per min |

| Cooling | Water Cooled 3/4 Ton capacity for a Lamp |

| Lamp Power | 6 KW / 9 KW |

| Power Supply | Transformer type with half- and full-power control Electronic Ballast type variable from 10% to 100% |

| Safety | Shutters Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Flexo, Gravure Printing machines. |

| Substrates | Paper, Boards, Plastics |

| Curing width | 30 inches |

| Curing Speed | 150/200 mtrs per min |

| Cooling | Water Cooled 3/4 Ton capacity for a Lamp |

| Lamp Power | 9 KW / 12 KW |

| Power Supply | Transformer type with half- and full-power control Electronic Ballast type variable from 10% to 100% |

| Safety | Shutters Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Offset Printing machines, Flexo, Gravure, Web offset machines. |

| Substrates | Paper, Boards, Plastics |

| Curing width | 40 inches |

| Curing Speed | 150/200 mtrs per min |

| Cooling | Water Cooled 3/4 Ton capacity for a Lamp |

| Lamp Power | 12 KW / 16 KW |

| Power Supply | Transformer type with half- and full-power control Electronic Ballast type variable from 10% to 100% |

| Safety | Shutters Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Offset Printing machines, Flexo, Gravure, Web offset machines. |

| Substrates | Paper, Boards, Plastics |

LED is Light Emitting Diode which generates high intense UV radiation utilizing less power.

This is the new development which replaces the conventional Mercury Vapour and Metal Halide lamps which are more hazardous.

LED is having UV-A and UV-C type wavelengths. The UV-A lamps are 365nm to 410nm.

LED UV intensity varies from 6W to 30W per sq.cm.

LED generates Cool UV light at the front end and heat at the back end. So it requires less cooling.

High Quality Lens are used to concentrate UV radiation on the substrate.

LED can be instantly switch ON/OFF which gives good control over the LED operation and saves the power and machine conditions.

| LED UV | Conventional UV |

|---|---|

| Less Power Consumption (20% of conventional UV) | High Power consumption |

| Instant ON/OFF Power Varied with Simple system |

Continuous Lighting intensity can be varied with complex power control system |

| Less Heat generation | Very high temperature generated leads to Fire accidents |

| Less Cooling required | Complex cooling required |

| Normal Voltage Application varies 200V to 400V | High Voltage application varies from 800V to 2000V |

| Very compact | Complex System |

| Modular Switching Possible Every 50mm can be ON/OFF |

No Modular switching possible |

| Life : 20000 hours | Life : 1000 hours |

Below mentioned are few models for Conveyor UV (LED UV System)

| Curing width | 12 inches |

| Curing Speed | 30 mtrs per min |

| Cooling | Air Cooled |

| Total Power | 1000 watts |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | screen printing, coating |

| Substrates | Paper, Boards , Plastics |

| Curing width | 20 inches |

| Curing Speed | 30 mtrs per min |

| Cooling | Air Cooled |

| Total Power | 1600 watts |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | screen printing, coating |

| Substrates | Paper, Boards, Plastics |

| Curing width | 30 inches |

| Curing Speed | 30 mtrs per min |

| Cooling | Air Cooled |

| Total Power | 2500 watts |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | screen printing, coating |

| Substrates | Paper, Boards, Plastics |

| Curing width | 40 inches |

| Curing Speed | 30 mtrs per min |

| Cooling | Air Cooled |

| Total Power | 3000 watts |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | screen printing, coating |

| Substrates | Paper, Boards, Plastics |

Below mentioned are few models for Interdeck UV (LED UV System)

| Curing width | 12 inches |

| Curing Speed | 150 mtrs per min |

| Lamp Power | 700 watts |

| Intensity of UV | 20 watts per cm. |

| Wavelength | 365nm to 410nm. (UV-C optional) |

| Cooling | Water Cooled 1 Ton chiller capacity for a Lamp |

| Total Power | 3 KW |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Flexo, Narrow Web offset machines. |

| Substrates | Paper, Boards, Plastics |

| Curing width | 20 inches |

| Curing Speed | 150 mtrs per min |

| Lamp Power | 1400 watts |

| Intensity of UV | 20 watts per cm. |

| Wavelength | 365nm to 410nm. (UV-C optional) |

| Cooling | Water Cooled 1 Ton chiller capacity for a Lamp |

| Total Power | 3.6 KW |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Flexo, Gravure, Narrow Web offset machines. |

| Substrates | Paper, Boards, Plastics |

| Curing width | 30 inches |

| Curing Speed | 150 mtrs per min |

| Lamp Power | 3500 watts |

| Intensity of UV | 20 watts per cm. |

| Wavelength | 365nm to 410nm. (UV-C optional) |

| Cooling | Water Cooled 1.5 Ton chiller capacity for a Lamp |

| Total Power | 5 KW |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Offset Printing machines, Flexo, Gravure, Web offset machines. |

| Substrates | Paper, Boards, Plastics |

| Curing width | 40 inches |

| Curing Speed | 150 mtrs per min |

| Lamp Power | 4000 watts |

| Intensity of UV | 20 watts per cm. |

| Wavelength | 365nm to 410nm. (UV-C optional) |

| Cooling | Water Cooled 1.5 Ton chiller capacity for a Lamp |

| Total Power | 6 KW |

| Power Supply | Electronic Ballast type variable from 10% to 100% |

| Safety | Temperature controller protect the Lamp temperature increase. Water circulation detection for better cooling Controlled by PLC |

| Application | Offset Printing machines, Flexo, Gravure, Web offset machines. |

| Substrates | Paper, Boards, Plastics |

Auto stacker is used for stacking cured substrates attached to a conveyor system to collect the substrates at the height of 900mm there are two models available

Used to 30 inches conveyor application with Auto Pile Up-down facility

Used to 40 inches conveyor application with Auto Pile Up-down facility

Teflon (PTFE) belts and belting materials are available for applications that require superior release characteristics, permeability for rapid dryng, dimensional and thermal stability, and the dynamic strength to stand up to the most rigorous operating conditions. It can withstand upto 160 deg and ranging width of 200nm to 1 mtr. The unique behavior of these materials results in a product that is more practical and cost-effective than conventional belting materials

Lamp is made of high quality Quartz glass, imported from US. The Lamp will be having the wattage of 200wpi to 400wpi. Curing width will be 6” to 50”. The life of the lamp will be 100hours

The Transformers is made up of copper insulated with H-Class Material to withstand high temperature and voltage. The Transformers are oil Sealed.

Blowers are used to remove the heat from the machine. The blowers blows the hot air out through a hose.

A variable Frequency Drive (VFD) is a type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the electric motor. Other names for a VFD are variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive, Microdrive, and inverter

LEDs are small, very efficient solid bulbs. New LED bulbs are grouped in clusters with diffuser lenses which have brodened the applications for LED use in the home. LED technology is advancing rapidly, with many new bulb styles available